5.2. Roll radius monitoring

5.2.2. Methods of measurement

There are two methods available for roll radius measurement: Thick Sum and Ratio.

According to the configuration of the encoders, please choose the proper method for the specific system.

5.2.2.1. Thick Sum

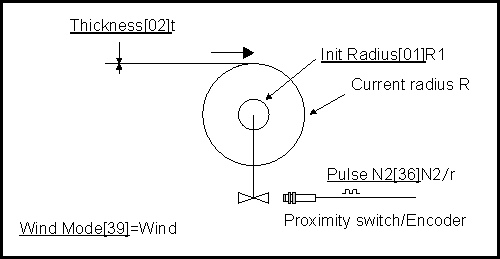

The controller counts the pulses generated by the proximity switch which mounted on the material roll, with the total pulses N and Init Radius[01] R1, the roll radius R can be got according to the following formula:

Wind: R = R1 + t*(N/N2)

Unwind: R = R1 - t*(N/N2)

R: Current roll radius

R1: Init Radius[01]

t: Material Thickness[02]

N: Total pulses

N2: Pulse N2[36]/r

The ˇ°Thick Sumˇ± method will use the following parameters:

-

Init Radius[01]

The initial radius, this value can be reset when in password screen by pressing LOCK key, the radius will be reset to Init Radius[01] automatically when reel exchange is performs.

-

Thickness[02] The real thickness of the material(web), in mm.

-

Max Radius[32] The maximum radius of the roll, set the proper value according to the real condition.

-

Min Radius[33] The minimum radius of the roll, set the proper value according to the real condition.

-

Pulse N2[36] Pulses/revolution of the material roll.

-

Calc Cycle[37] When the sum of pulses reach Calc Cycle[36], the calculation of radius will be updated once.

-

Wind Mode[39] This affect the behavior of increment and decrement of radius, in winding systems, radius increases while in unwinding system, radius decreases.

5.2.2.2. Ratio

When using this monitoring method, the controller counts the pulses generated by the proximity switches which mounted on the material roll and main roll(i.e. the tension sensing roller), the radius of the material will be calculated automatically with the setting parameters. Thickness[02] and Wind Mode[39] are not used in ratio method.

The following parameters must be set properly:

-

Max Radius[32] The maximum radius of the roll, set the proper value according to real condition.

-

Min Radius[33] The minimum radius of the roll, set the proper value according to real condition.

-

Radius R0[34] The radius of the tension sensing roller.

-

Pulse N1[35] Pulses/revolution of the tension sensing roller.

-

Pulse N2[36] Pulses/revolution of the material reel.

-

Calc Cycle[37] When the sum of the pulses reach Calc Cycle[37], the calculation of radius will be updated once. Calc Cycle[37] affects the interval and precision of the radius calculation, the greater value, the more precision but longer interval.