4.3. Taper tension control

4.3.1. Introduction

In winding systems, decreasing the tension while the winder radius increases is called taper tension control, this can make the inner of the winder tighten and the outer of the winder loosen, thus avoid slipping.

This function can be enabled by setting the Ctrl Mode[29] to Taper tension.

The greater Taper t1[30] coefficient, the greater change of the tension while increasing of the reel radius. If the taper t1 equals to 0, the controller will perform the constant tension control.

In unwinding systems, set Ctrl Mode[29] to Constant ctrl.

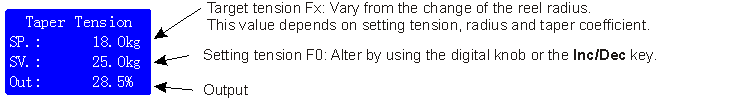

4.3.2. Taper tension screen

Note: The measured tension can be viewed on the 7-seg display when the kg/N indicator is lit.

Please debug by stepping through these steps:

-

Check if the measurement of tension is correct, if not, go to Chapter 4.

-

Check if the mounting and connection of the proximity switch is correct, check the output signal of the proximity switch.

-

Set the radius measurement related parameters to proper values.

-

First use manual operation and check whether the measured radius is right, if not, go to step 2.

-

Set the proper value for Taper t1[30] and starts, ensure that the desired control precision is achieved.