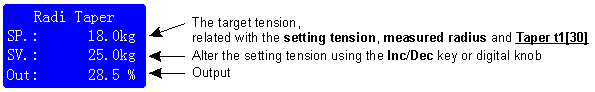

5.5. Taper tension control

The taper tension control function can also be accomplished in radius tension control systems.

The greater value for Taper t1[30], the greater change of the tension while increasing of the reel radius. If the Taper t1[30] equals to 0, the controller will perform the constant tension control.

The controller should be set as Constant ctrl mode in unwinding applications.

For the relationship between target tension, setting tension and the taper coefficient Taper t1[30], please refer to Section 4.3.

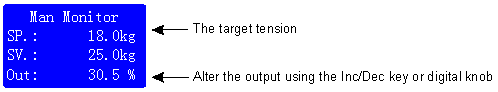

5.5.2. Manual mode

Note: When switching from automatic mode to manual mode, the controller will smooth the transition automatically.

5.5.3. Debug steps

-

Make sure that the mounting and connection of the proximity switch/encoder is correct, and check if the proximity switch/encoder works correctly.

-

Set proper values for the taper tension control related parameters.

-

Set Function[28] to Radius control.

Set Ctrl Mode[29] to Taper tension.

-

Set proper values for the radius measurement parameters, see Section 5.2.

-

Set Torque[38] according to the actual brake/clutch.

-

Set proper values for Taper t1[30].

-

Set proper values for parameters 08-15.

-

-

Operate in manual mode to test if the measurement of the radius is correct, if not, goto step 2.

-

Adjust the taper coefficient Taper t1[30] and the output, after the tension of the web is stable, switch to automatic mode, the controller will smooth the transition automatically.